About Us

Established In 1947, Florida Southern Plywood Is A Full Line Specialty Plywood, Cabinet & Lumber Distributor, From Our Warehouse Facilities In Jacksonville, Florida.

Our Warehouse

- 5909 West 5th Street, Jacksonville, FL 32254

- (904) 786-4382

- Open Mon - Fri 8am - 5pm

- info@fspcjax.com

About Our Veneers

Florida Southern Plywood offers more than 100 wood species of wood veneer edge banding, with a complete selection of backer types.

Florida Southern Plywood stocks 20 varieties of veneer (with a wood backer) and has the ability to source more than 100 different wood species from around the world. We also stock matching wood edge banding with or without glue, depending on your application process or needs.

Florida Southern Plywood is able to offer some of the most competitive pricing on wood veneer and edge banding from VeneerTech, the industry leader in Veneer Technology.

If you don’t see what you are looking for, please don’t hesitate to give us a call!

available species

All veneers subject to availability, limited species in stock

Light Veneers

Medium Veneers

Dark Veneers

Veneer Cuts

The manner in which veneers are cut is an important factor in producing the various visual effects obtained. Two woods of the same species, but with their veneer cut differently, will have entirely different visual character even though color values are similar. In plywood manufacture, there are four principal methods of cutting veneer:

The half log, of flitch, is mounted with the heart side flat against the guide plate of the slicer and the slicing is done parallel to a line through the center of the log. This produces a figure to that of plain sawn lumber.

The half log, of flitch, is mounted with the heart side flat against the guide plate of the slicer and the slicing is done parallel to a line through the center of the log. This produces a figure to that of plain sawn lumber.

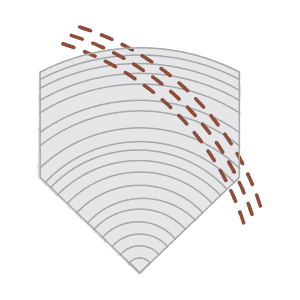

The quarter log, or flitch, is mounted on the guide plate so that the growth rings of the log strike the knife at approximately right angles. This produces a series of stripes, straight in some woods, varied in others.

The quarter log, or flitch, is mounted on the guide plate so that the growth rings of the log strike the knife at approximately right angles. This produces a series of stripes, straight in some woods, varied in others.

Rift-cut veneer is produced in the various species of Oak. Oak has medullary ray cells, which radiate from the center of the log like the spokes of a wheel. The rift, or comb grain effect, is obtained by slicing slightly across the medullary rays. This accentuates the vertical grain and minimizes the flake.

Rift-cut veneer is produced in the various species of Oak. Oak has medullary ray cells, which radiate from the center of the log like the spokes of a wheel. The rift, or comb grain effect, is obtained by slicing slightly across the medullary rays. This accentuates the vertical grain and minimizes the flake.

The log is mounted centrally in the lathe and turned against a razor sharp blade, like unwinding a roll of paper. Since the cut follows the log’s annular growth rings, a bold grain figure is produced. Rotary cut veneer is exceptionally wide, and matching at veneer joints is relatively difficult. Almost all softwood plywood is cut in this manner. Lengths in all hardwoods are limited to 10 feet.

The log is mounted centrally in the lathe and turned against a razor sharp blade, like unwinding a roll of paper. Since the cut follows the log’s annular growth rings, a bold grain figure is produced. Rotary cut veneer is exceptionally wide, and matching at veneer joints is relatively difficult. Almost all softwood plywood is cut in this manner. Lengths in all hardwoods are limited to 10 feet.